To straighten aluminum arrows, heat the shaft using a heat gun or flame until it becomes soft, then carefully straighten it by bending it in the opposite direction of the curve. Avoid excessive force to prevent breaking the arrow.

Straightening aluminum arrows is a common practice among archers and bowhunters. Whether your arrows have been damaged during use or have become bent over time, restoring their straightness is essential for achieving accurate shots. In this guide, we will explain the simple yet effective technique of straightening aluminum arrows.

By following these steps, you can ensure that your arrows are in optimal condition and ready for your next archery session. Let’s dive in and learn how to straighten aluminum arrows using a straightforward and efficient method.

Recognizing Bent Or Misaligned Arrows

Straightening aluminum arrows is essential for accuracy in archery. Recognizing bent or misaligned arrows is the first step, followed by carefully applying pressure to fix the issue.

Aluminum arrows are known for their durability and straightness. However, over time, these arrows can become bent or misaligned, affecting their accuracy and performance. In this section, we will discuss how to recognize bent or misaligned arrows through a physical examination and testing their spin for accuracy.

Physical Examination For Visible Deformities:

- Inspect the arrow shaft visually, looking for any signs of bending or warping.

- Check for any dents, scratches, or other visible damages that could indicate misalignment.

- Gently roll the arrow on a flat surface to see if it spins smoothly without wobbling.

- Pay attention to the fletching, ensuring that it is intact and aligned properly with the arrow shaft.

- Use a straight edge or arrow straightening tool to assess whether the arrow deviates from a straight line.

Testing Arrow Spin For Accuracy:

- Choose a safe location, such as an indoor range or an open outdoor space, to perform the test.

- Securely attach the arrow to a bowstring and draw it back, ensuring the arrow is aligned with the bow’s rest.

- Release the arrow, observing its flight path and stability.

- Pay attention to any erratic movements or deviations from a straight trajectory.

- Note the impact point of the arrow on the target, as inconsistent impacts could indicate a bent or misaligned arrow.

By conducting a physical examination and testing arrow spin for accuracy, you can easily recognize bent or misaligned aluminum arrows. Proper identification allows you to take necessary steps to straighten these arrows, ensuring optimal performance and improved accuracy in your archery endeavors.

Gathering The Necessary Supplies

To straighten aluminum arrows effectively, gather the necessary supplies such as a heat source, a solid surface, and a cloth. Apply heat to the bent area and slowly straighten the arrow using the cloth, ensuring to handle it carefully.

To straighten your aluminum arrows effectively, you will need to gather a few important supplies. Here are the essential items you’ll need:

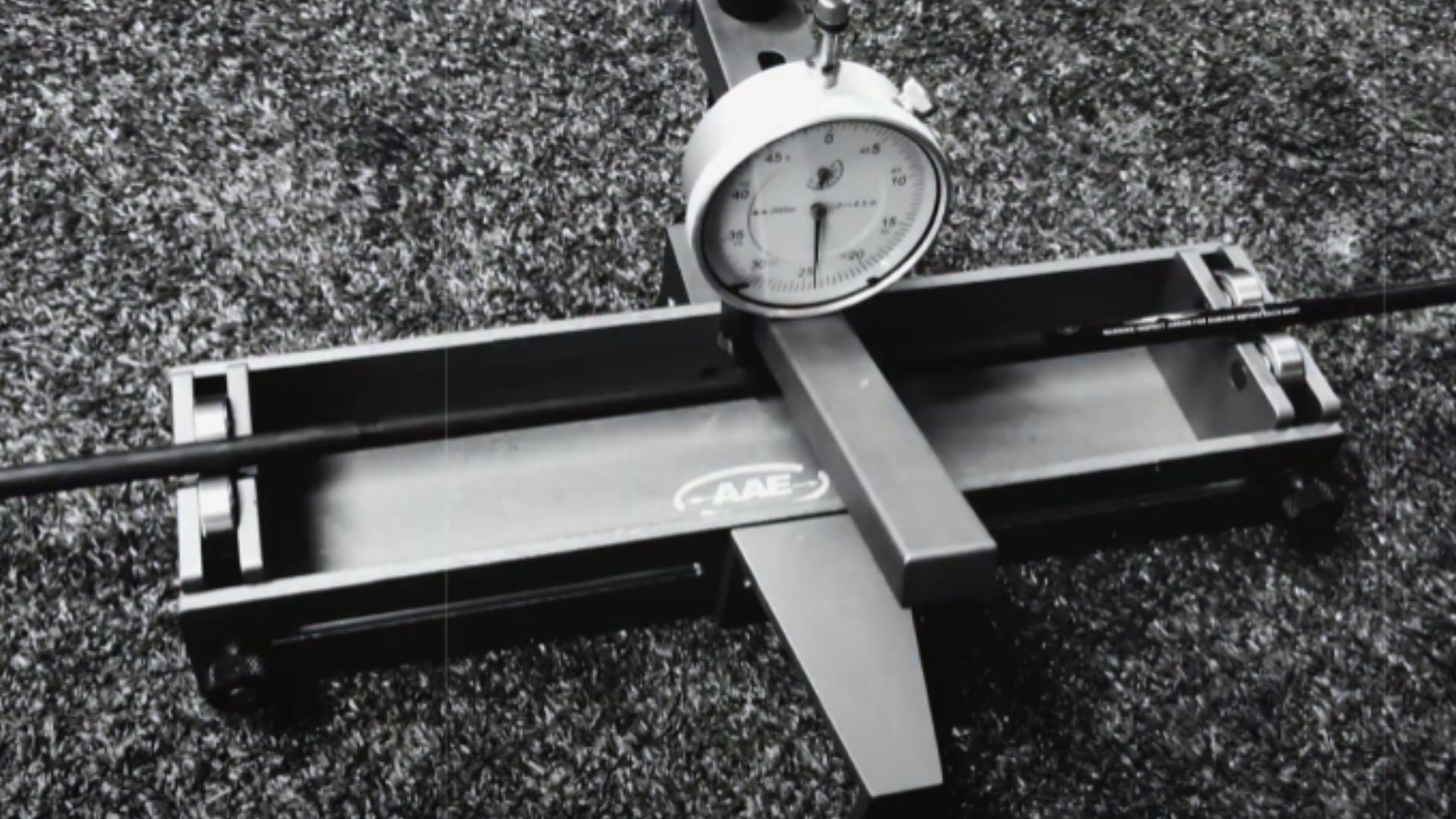

- Arrow straightening tool: Having an arrow straightening tool is crucial for this process. This specialized tool helps to straighten the shaft of the arrow, ensuring optimal performance when shooting. It is designed to carefully bend the arrow back into alignment without damaging it.

- Heat source (e.g., hairdryer): It’s important to apply heat to the aluminum shaft of the arrow in order to make it more pliable and easier to straighten. A hairdryer can serve as a reliable heat source for this purpose. By directing the warm air onto the shaft, you’ll be able to effectively manipulate its shape.

- Protective gloves and safety glasses: Safety should always come first when working with equipment and tools. Wear protective gloves and safety glasses to shield your hands and eyes from any potential harm during the straightening process. These accessories will provide the necessary protection while allowing you to handle the arrows with confidence.

By gathering these essential supplies, you’ll be well-prepared to embark on the journey of straightening your aluminum arrows effectively and ensuring their optimum performance in archery.

Understanding Different Straightening Techniques

Aluminum arrows can be straightened using various techniques to ensure accuracy and precision during archery. Learn about the different methods available, such as heat straightening and mechanical straightening, to effectively straighten your aluminum arrows.

When it comes to straightening aluminum arrows, it’s important to understand the different techniques available. This section will explore two popular methods: cold straightening and heat straightening. Whether you’re a beginner or an experienced archer, knowing these techniques will help you maintain the accuracy and performance of your arrows.

Cold Straightening Method:

- Visual Inspection: Begin by visually inspecting your aluminum arrows for any visible bends or deformities.

- Manual Straightening: If you notice a slight bend, you can use your hands to manually straighten the arrow. Apply gentle pressure to the affected area while ensuring the shaft remains evenly supported.

- Mechanical Straightening: For more pronounced bends, using a specialized arrow straightening tool can be beneficial. These tools allow for precise adjustments and ensure all bends are eliminated.

Heat Straightening Method:

- Heating the Arrow: To straighten severely bent aluminum arrows, heat treatment is often necessary. Use a heat source such as a torch or even boiling water to heat the affected area of the arrow.

- Applying Pressure: Once the arrow is heated, carefully apply pressure in the opposite direction of the bend. You can use a flat surface or a straightening tool designed to withstand the heat.

- Quenching: After straightening, it’s crucial to rapidly cool the arrow. Submerge the arrow in water or use compressed air to cool it down quickly. This process helps to retain the corrected shape.

By understanding these different straightening techniques, you can effectively address bends and deformities in your aluminum arrows. Whether you prefer the convenience of cold straightening or the precision of heat straightening, both methods offer effective solutions for arrow maintenance. So, the next time your arrows need straightening, give these techniques a try for optimal performance on the archery range.

Preparing Your Workspace And Equipment

To straighten aluminum arrows, it is essential to prepare your workspace and equipment. By ensuring a clean and organized environment, you can effectively straighten your arrows without any hassle, resulting in improved performance during archery activities.

Safety Precautions:

- Always wear protective gear such as gloves and safety glasses to prevent injuries during arrow straightening.

- Ensure adequate ventilation in your workspace to minimize the inhalation of any fumes that may be emitted during the process.

- Keep flammable materials away from your work area to reduce the risk of fire or accidents.

- Use caution when handling tools and equipment, making sure to follow the manufacturer’s instructions for safe usage.

- Keep a first aid kit handy in case of any minor injuries.

Setting Up A Clean And Organized Workspace:

- Start by clearing any clutter from your work area to create a clean and organized space.

- Place a sturdy work table or bench in the center of your workspace to provide a stable surface for arrow straightening.

- Ensure proper lighting in the area so that you can clearly see the arrows and any imperfections.

- Keep all the necessary tools and equipment within reach to save time and effort while working.

- Use containers or organizers to arrange smaller items such as screws, nuts, or washers to prevent loss or confusion during the process.

Remember, safety should always be your top priority when straightening aluminum arrows. By following these safety precautions and setting up a clean and organized workspace, you can ensure a smooth and efficient arrow straightening process.

Cold Straightening Method

Straightening aluminum arrows can be effectively achieved using the cold straightening method. By carefully applying pressure and techniques, you can restore the arrows’ straightness without compromising their structural integrity.

Assessing The Bend Or Misalignment

- Firstly, visually examine the aluminum arrow to determine the extent of the bend or misalignment.

- Ensure you have a clear understanding of the specific area that needs to be straightened.

- Evaluate the severity of the bend by comparing it to a straight arrow.

- Take note of any other damages or bends along the arrow shaft.

- Remember to exercise caution while handling the arrow to avoid injury.

Using The Arrow Straightening Tool To Apply Pressure

- Start by selecting an appropriate arrow straightening tool based on the size and type of arrow you are working with.

- Place the aluminum arrow securely in the straightening tool, ensuring it is positioned correctly.

- Apply gentle and consistent pressure to the bent section of the arrow using the tool.

- Gradually increase the applied pressure, making sure not to exert excessive force that could damage the arrow.

- Take your time, as rushing the process may result in further misalignment or damage to the arrow shaft.

Testing The Arrow’s Straightness

- Once you believe you have straightened the aluminum arrow, take a moment to inspect it visually again.

- Look for any remaining signs of the initial bend or misalignment.

- Roll the arrow gently on a flat surface to verify its straightness.

- If the arrow tends to roll to one side or displays any wobbling, it may still require further straightening.

- Repeat the straightening process as necessary until the arrow is perfectly straight.

Remember, straightening aluminum arrows using the cold straightening method requires precision and patience. Take your time to ensure the best results and never hesitate to seek professional assistance if needed.

Heat Straightening Method

Straightening aluminum arrows can be achieved using the heat straightening method, which involves heating the arrow and gradually straightening it. This technique ensures precision and accuracy in arrow flight.

Applying Heat To The Bent Area:

- Step 1: Begin by heating the bent area of the aluminum arrow using a heat source such as a blowtorch or a heat gun. Ensure that the heat is evenly applied to the entire bent section.

- Step 2: Slowly move the heat source back and forth along the bent area, focusing on the most severely bent regions. This will help to gradually soften the metal and make it malleable for straightening.

- Step 3: Be cautious not to overheat the arrow, as excessive heat can weaken the metal or cause it to warp. Continuously monitor the temperature to prevent any damage to the arrow shaft.

Using The Arrow Straightening Tool To Straighten The Arrow:

- Step 1: Once the aluminum arrow has been heated, carefully handle the arrow straightening tool. This tool is designed specifically for straightening arrows and consists of two adjustable portions.

- Step 2: Position the arrow in the tool, aligning the bent area within the tool’s jaws. Ensure that the jaws securely grip the arrow shaft without causing any damage.

- Step 3: Gradually close the jaws of the arrow straightening tool, applying gentle pressure to the bent area. Slowly straighten the arrow by carefully adjusting the tool until the desired level of straightness is achieved.

Cooling And Testing For Straightness:

- Step 1: Allow the aluminum arrow to cool naturally after the heat straightening process. Placing it in a cool and well-ventilated area will speed up the cooling process.

- Step 2: Once the arrow has cooled down, visually inspect the shaft for any signs of remaining bends or deformations. Rotate the arrow and observe it from different angles to ensure it is straight.

- Step 3: To further test for straightness, gently roll the arrow across a flat surface, such as a table or countertop. If the arrow rolls smoothly without any wobbling or deviations, it indicates that it is straightened properly.

Remember, heat straightening requires caution and precision. If you are uncertain about performing this process yourself, it is advisable to seek professional assistance to avoid any potential damage to the arrow.

Storage And Transportation

Learn how to straighten aluminum arrows with ease for optimal storage and transportation. Discover step-by-step instructions on maintaining the perfect arrow shape for improved performance.

Whether you’re a seasoned archer or just starting out, proper storage and transportation of your aluminum arrows is essential to maintain their straightness and overall performance. In this section, we will explore some key considerations to keep in mind when it comes to storing and transporting your arrows.

By following these guidelines, you can help prevent any potential damage or bending that may occur during transit.

Using Arrow Tubes Or Cases:

- Investing in arrow tubes or cases is a great way to protect your aluminum arrows during storage and transportation.

- Arrow tubes provide a secure and organized way to store your arrows, preventing them from shifting or colliding with other items.

- Cases with foam inserts offer additional cushioning, reducing the risk of any impact-related damage.

- When choosing an arrow tube or case, make sure it is the appropriate size for your arrows to ensure a snug fit.

Avoiding High Temperatures And Excessive Pressure:

- Extreme temperatures can have a negative impact on the straightness of aluminum arrows.

- Avoid storing your arrows in places with high temperatures, such as direct sunlight or the trunk of a vehicle during hot summer months.

- Similarly, excessive pressure can lead to bending or warping of the arrows. Avoid placing heavy items on top of your arrows during storage or transportation.

By following these simple guidelines, you can ensure the longevity and optimal performance of your aluminum arrows. Proper storage and transportation is key to maintaining their straightness, ultimately resulting in more accurate and consistent shots on the archery range or in the field.

Regular Inspections And Tune-Ups

Regular inspections and tune-ups are essential for maintaining the straightness of aluminum arrows. By regularly assessing and adjusting their alignment, you can ensure optimal performance and accuracy while shooting.

Regular inspections and tune-ups are crucial for maintaining straight and properly aligned aluminum arrows. By checking for any new bends or misalignments and re-straightening as needed, you can ensure optimal performance and accuracy. Here are some key steps to follow:

- Inspect the shaft: Carefully examine the arrow shaft for any signs of bending or misalignment. Look for noticeable bends, twists, or other irregularities that may affect the arrow’s flight.

- Check the tips: Inspect the arrow tips for any damage or excessive wear. Make sure they are securely attached and aligned with the shaft.

- Review the fletching: Examine the fletching, which refers to the feather or plastic vanes attached to the back of the arrow. Ensure they are intact, properly aligned, and free from any damage or deformation.

- Align the nock: The nock is the slot on the end of the arrow where the bowstring is attached. Ensure the nock is straight, properly aligned, and securely attached to the shaft.

- Use a straightening tool: If you detect any bends or misalignments, use a proper arrow straightening tool to carefully straighten the shaft. Follow the manufacturer’s instructions to avoid causing further damage.

- Inspect arrow components: While straightening the arrow, take the opportunity to inspect other components such as arrowheads, inserts, or collars. Replace or repair any damaged parts.

By regularly inspecting and tuning up your aluminum arrows, you can maintain their straightness and enhance your shooting accuracy. Remember, a well-tuned arrow can make a significant difference when it comes to hitting your target consistently.

Over-Straightening Or Weakening The Arrow

Straightening aluminum arrows properly is essential in order to avoid over-straightening or weakening them. Follow these steps to ensure your arrows remain in optimal condition and trajectory.

Signs To Watch Out For:

- Bent or kinked arrows: If you notice any visible bends or kinks in your aluminum arrows, it may indicate that they have been over-straightened or weakened.

- Inconsistent flight patterns: Overly straightened arrows can result in inconsistent flight patterns, causing your shots to be less accurate.

- Arrowheads coming off: Weakening the arrow through over-straightening can lead to loose arrowheads or even their complete detachment during shots.

Steps To Rectify The Issue:

- Assess the damage: Examine your aluminum arrows carefully, looking for any signs of bends, kinks, or weakened areas.

- Avoid excessive pressure: When attempting to straighten your arrows, apply gentle and controlled pressure, avoiding any excessive force that could further weaken them.

- Use a straightening tool or equipment: Invest in a quality arrow straightening tool or utilize equipment specifically designed for this purpose. They can help you exert precise pressure on the arrow shaft without causing damage.

- Apply gradual pressure: Begin straightening by applying gradual pressure on the bent or kinked area of the arrow. Slowly work your way along the shaft, making sure to distribute pressure evenly.

- Check for progress: Regularly reassess the arrow’s straightness while straightening. Take breaks if needed to prevent the arrow from overheating or experiencing excessive stress.

- Test the arrow’s spine: Once you have straightened the arrow to a satisfactory level, test its spine by flexing it gently. If it returns to its original straight position without any signs of bending, you have successfully rectified the issue.

- Consult a professional: If you are unsure about how to straighten your aluminum arrows properly, or if you have tried and failed to achieve the desired results, consider consulting an experienced archery professional who can assist you.

Remember, it is crucial to strike a balance when straightening aluminum arrows. While some level of straightening may be necessary for optimal performance, excessive manipulation can weaken the arrows. By following these steps and being cautious, you can ensure that your arrows remain durable and maintain consistent performance.

Inconsistent Straightening Results

Aluminum arrows can sometimes produce inconsistent results when straightened. Discover effective techniques for achieving desired arrow alignment and tips for avoiding potential issues.

Have you ever tried straightening aluminum arrows but ended up with inconsistent results? Don’t worry, you’re not alone. In this section, we’ll explore possible causes for this issue and share some adjustments and tips to help you achieve better and more consistent straightening results.

Possible Causes

- Lack of proper equipment: Using the wrong tools or not having the necessary equipment can lead to inconsistent straightening results. Ensure you have a reliable arrow straightening device designed specifically for aluminum arrows.

- Incorrect technique: The way you apply pressure and manipulate the arrows during the straightening process can play a significant role in the outcome. Make sure you understand the correct technique and follow it diligently.

- Over- or under-straightening: It’s possible to overdo or underdo the straightening process, resulting in inconsistent arrow shape. Pay attention to the amount of pressure you apply when straightening to ensure you achieve the desired results.

- Warped or damaged arrows: If the arrows are already warped or damaged before straightening, it can impede your efforts to achieve consistent results. Inspect your arrows carefully before attempting to straighten them and discard any that are severely compromised.

Adjustments And Tips For Better Results

- Slow and steady: Take your time when straightening aluminum arrows. Rushing the process can lead to mistakes and inconsistent outcomes. Patience and a gradual approach will yield better results.

- Use consistent pressure: Apply consistent pressure along the length of the arrow shaft when straightening. Avoid focusing too much on one section as it can cause deformities in other areas.

- Heat treatment: Heat can help loosen the molecular structure of the aluminum, making it easier to straighten. However, be cautious not to overheat the arrows as it can weaken the material. Heat them slowly and evenly using a heat gun or warm water before straightening.

- Test arrows regularly: Regularly test the straightness of your arrows throughout the process to monitor your progress. This will allow you to make necessary adjustments and ensure you are on the right track.

Remember, achieving consistent straightening results with aluminum arrows requires practice, patience, and attention to detail. By understanding the possible causes and implementing the adjustments and tips provided, you can improve your straightening technique and obtain more reliable outcomes.

So, let’s dive into the exciting world of straightening aluminum arrows and master the art!

Consistency In Technique And Practice

Discover the key to straightening aluminum arrows with consistency in technique and practice. Master the art of arrow straightening with these essential tips and refine your skills for optimal performance.

To straighten aluminum arrows effectively, it is crucial to develop consistency in technique and practice. By mastering this skill, you can improve your shooting accuracy and arrow performance. Here are some tips to help you achieve consistency in technique and practice:

- Developing muscle memory:

- Consistently repeat the same motion when shooting the arrow to develop muscle memory.

- Engage in regular practice sessions to reinforce the correct technique and improve muscle memory.

- Muscle memory helps you maintain consistent form, resulting in more accurate shots.

- Regularly shooting and evaluating arrow performance:

- Shoot arrows regularly to refine your technique and identify any issues.

- Evaluate the performance of each arrow after each shot to assess consistency and identify any potential problems.

- This evaluation allows you to make necessary adjustments in your technique to ensure better accuracy in the future.

By consistently practicing and evaluating your shots, you can develop muscle memory and improve your overall shooting technique. Remember to be patient with yourself as straightening aluminum arrows requires time and practice. With persistence and dedication, you’ll soon see improvements in your accuracy and precision.

Happy shooting!

Seeking Professional Help And Guidance

Looking for professional guidance to straighten aluminum arrows? Get expert help in realigning your arrows for optimal performance and accuracy. Trust the professionals to ensure your arrows are in perfect condition for your next archery session.

When it comes to straightening aluminum arrows, it’s important to recognize when the task should be left to a professional. Seeking guidance from experienced archery technicians can save you time, effort, and potential damage to your arrows. Here are some ways you can connect with professionals for expert advice:

- Consulting an experienced archery technician: A qualified technician can offer valuable insights into the straightening process, ensuring that you don’t make any mistakes that could compromise the integrity of your arrows. They have the knowledge and skills to assess the condition of your arrows and provide appropriate recommendations. The benefits of consulting a professional include personalized guidance and the assurance that your arrows are in capable hands.

- Joining archery communities and forums for advice: Online communities and forums dedicated to archery can be a great resource for beginners and experienced archers alike. These platforms allow you to connect with other archery enthusiasts who may have encountered similar issues with straightening aluminum arrows. By participating in discussions, asking questions, and sharing experiences, you can gain valuable insights and tips from the collective wisdom of the community.

Remember, the decision to seek professional help ultimately depends on your level of comfort and expertise. Straightening aluminum arrows requires precision and care, so if you’re unsure or hesitant, it’s wise to reach out to professionals for guidance.

Frequently Asked Questions Of How To Straighten Aluminum Arrows

Can You Straighten An Aluminum Arrow?

No, it is not possible to straighten an aluminum arrow.

Can You Straighten Bent Arrows?

Yes, we can straighten bent arrows professionally with careful attention to detail.

Can Bent Aluminum Be Straightened?

Yes, bent aluminum can be straightened with careful techniques.

Are Aluminum Arrows Straighter Than Carbon?

Yes, aluminum arrows are typically straighter than carbon arrows.

Conclusion

Straightening aluminum arrows is a crucial step in ensuring their accuracy and performance. By following the steps outlined in this blog post, you can effectively straighten your arrows at home using simple tools and techniques. Remember to always inspect your arrows for signs of damage before straightening and proceed with caution to avoid causing further harm.

Properly straightened arrows will enhance your shooting experience by improving accuracy and consistency. Taking the time to straighten your arrows also ensures that they last longer, saving you money in the long run. So, don’t underestimate the importance of arrow straightening in archery.

With practice and care, you can master this skill and enjoy the full potential of your aluminum arrows. Happy shooting!