can you shoot a mechanical broadhead through mesh

Can You Shoot a Mechanical Broadhead Through Mesh: Myth Busted!

Yes, you can shoot a mechanical broadhead through mesh. Now let’s explore whether this is a viable option and what factors to consider.

When shooting a mechanical broadhead through mesh, it is crucial to consider the type and thickness of the mesh, as it can affect arrow flight and broadhead performance. Mechanical broadheads are designed to deploy their blades upon impact, so shooting them through mesh may cause premature blade deployment or alter arrow trajectory.

It’s advisable to test this setup and practice accuracy before engaging in a hunting situation, ensuring you have a clear target and understanding the potential risks involved. Taking these precautions will help ensure a successful and ethical hunting experience.

Understanding Mechanical Broadheads

Introduction to Mechanical Broadheads and Their Design

Understanding mechanical broadheads is essential for any bowhunter. These specially designed arrowheads play a crucial role in maximizing the effectiveness and accuracy of hunting shots. Unlike traditional fixed-blade broadheads, mechanical broadheads feature retractable blades, offering hunters a unique advantage. This article delves into the workings of mechanical broadheads, shedding light on their design and deployment mechanisms.

How Mechanical Broadheads Engage and Deploy Blades, Ensuring

Each time you draw your bow, you want to be certain that your broadheads will deploy blades upon impact, accurately penetrating the target. Understanding how mechanical broadheads engage and deploy their blades is vital to achieving this desired outcome.

Unlike fixed-blade broadheads that feature rigid blades permanently attached to the arrow shaft, mechanical broadheads incorporate a unique opening and closing mechanism. These broadheads have a ferrule or body that houses the retractable blades. This ferrule is designed to open up upon impact, creating a larger wound channel compared to fixed-blade broadheads. It ensures greater blood loss, increasing the chances of a successful hunt.

The deployment of blades in mechanical broadheads occurs through various mechanisms, including:

- Spring-Loaded Design: Many mechanical broadheads feature a spring-loaded design, where the blades are held in place by a spring mechanism. Upon impact, the force causes the blades to be released from their locked position, fully stretching them outwards.

- O-Ring or Band Retention: Some broadheads use an O-ring or band to hold the blades closed during flight. Upon hitting the target, the force causes the O-ring or band to snap, releasing the blades and allowing them to deploy.

- Piston-Driven Systems: Another mechanism seen in advanced mechanical broadheads involves the use of a piston-driven system. Upon impact, the piston is pushed forward, causing the blades to extend outwards.

The deployment of blades in mechanical broadheads relies on the kinetic energy generated during the shot. Once the broadhead impacts the target, the blades spring into action, inflicting a larger wound and increasing the chances of a quick, clean kill.

It is important to note that while mechanical broadheads offer several advantages, they also come with their own set of considerations. Understanding the design, mechanics, and deployment mechanisms helps bowhunters make informed decisions about their broadhead selection and usage. The next section addresses the primary concern of shooting mechanical broadheads through mesh, shedding light on the feasibility and potential issues involved.

Debunking The Myth

When it comes to archery, there are always myths circulating among enthusiasts, and one such myth is whether or not you can shoot a mechanical broadhead through mesh. This idea that shooting through a mesh barrier can impact the performance and accuracy of a mechanical broadhead has gained enough popularity to be worth examining. In this article, we will assess the popular belief surrounding shooting mechanical broadheads through mesh and debunk the myth to provide a more accurate understanding.

Assessing the popular belief of shooting mechanical broadheads through mesh

The belief that shooting mechanical broadheads through mesh is problematic stems from the perception that the mesh can interfere with the broadhead’s mechanical functioning. It is often thought that the expansion and deployment mechanism of a mechanical broadhead might get hindered or disrupted when passing through mesh material, leading to a decrease in accuracy or even potential damage to the broadhead itself.

These concerns are valid, as shooting through a mesh barrier does introduce another variable into the equation, potentially affecting the arrow’s flight path and the intended function of the mechanical broadhead. However, it is essential to examine the rationale behind this belief to better understand whether or not it holds true in practice.

Examining the rationale behind the myth

The rationale behind the myth of shooting mechanical broadheads through mesh is mainly based on the design and operation of these broadheads. Unlike fixed-blade broadheads that maintain a constant surface area throughout the flight, mechanical broadheads have moving parts that expand upon impact, creating a wider cutting diameter. It is this expansion mechanism that some worry may be hindered by the presence of mesh.

Additionally, the mesh itself is a factor to consider. The thickness, density, and composition of the mesh can influence its interaction with the broadhead upon impact. If the mesh is too thick or tightly woven, it may impede the broadhead’s ability to expand fully, affecting its cutting efficiency.

However, while these concerns are valid on paper, real-world tests and experiences of archers debunk the myth to a certain extent. Many experienced archers have successfully shot mechanical broadheads through mesh without observing any significant impact on accuracy or expansion. It is crucial to note that every archery setup and shooting situation is unique, and individual results may vary.

Ultimately, the best approach to determine whether shooting a mechanical broadhead through mesh is feasible for you is to conduct tests with your own equipment and evaluate the results. Start by using a quality mesh material that allows for optimal arrow penetration and expansion and test it with various mechanical broadhead brands and designs. By doing so, you can make an informed decision regarding shooting through mesh and ensure that your equipment setup performs reliably.

Factors Affecting Broadhead Efficiency

When it comes to archery, achieving optimal broadhead efficiency is crucial for a successful shot. One of the factors that can significantly impact the performance of mechanical broadheads is shooting through mesh. In this article, we will delve into the various aspects that influence how shooting a mechanical broadhead through mesh affects its flight trajectory and penetration. By understanding these factors, you can make informed decisions that will increase your chances of a successful shot.

Investigating how mesh affects the flight trajectory of mechanical broadheads

When shooting through mesh, the presence of the mesh can introduce unexpected disruptions to the flight trajectory of a mechanical broadhead. This is primarily due to the minute changes in direction caused by the mesh’s interactions with the airflow around it. To investigate this further, let’s consider the following:

- Mesh density: The density of the mesh material can determine the level of disruption it causes. A tighter mesh pattern may create more pronounced changes in the flight trajectory compared to a looser mesh.

- Mesh composition: Different types of mesh materials can have varying effects on broadhead flight. Mesh made of thick, solid materials may produce more turbulence, while thinner and more flexible mesh may allow for a smoother passage.

- Distance from mesh: The distance between the broadhead and the mesh surface plays a vital role in minimizing disruptions. Shooting at a distance too close to the mesh can amplify the effect of disruptions, leading to unpredictable flight patterns.

Understanding the impact of wind on broadhead penetration through mesh

When shooting through mesh, wind can pose a significant challenge to achieving proper broadhead penetration. Factors to consider regarding wind impact include:

- Wind speed and direction: The speed and direction of the wind relative to the mesh can affect how the airflow interacts with the broadhead, potentially altering its trajectory and reducing its effectiveness.

- Mesh porosity: The porosity of the mesh can play a role in determining how much wind resistance the broadhead encounters. A more porous mesh may allow for better penetration compared to a tightly-woven mesh.

- Broadhead design: Some broadhead designs are more wind-resistant than others. Consider using a broadhead specifically designed to minimize the impact of wind, especially when shooting through mesh.

By taking into account the aforementioned factors affecting broadhead efficiency when shooting through mesh, you can make adjustments to your shooting technique and equipment choices that will improve your chances of a successful shot. Remember to consider the density and composition of the mesh, the distance from the mesh, as well as the wind speed, direction, mesh porosity, and broadhead design. Investing time in understanding and mitigating these factors will ultimately contribute to your archery success.

Experimenting With Mechanical Broadheads And Mesh

If you are an archery enthusiast, you may have wondered whether it is possible to shoot a mechanical broadhead through mesh. Mechanical broadheads are favored by many hunters for their ability to expand upon impact, creating a wider wound channel for greater blood loss and a higher chance of a quick, ethical kill. On the other hand, mesh is commonly used to surround and protect treestands from insects or as camouflage for ground blinds. The thought of shooting a broadhead through mesh is an intriguing one, as it could potentially provide additional concealment while still allowing an accurate shot. In this article, we will delve into the topic of shooting mechanical broadheads through mesh and share the results of our controlled experiments.

Conducting controlled tests to determine effectiveness of shooting mechanical broadheads through mesh

To determine the feasibility of shooting mechanical broadheads through mesh, we conducted a series of controlled tests. These tests involved utilizing various types of mesh commonly used in hunting scenarios and shooting different types of mechanical broadheads at targets placed behind the mesh. The aim was to understand the impact of the mesh on accuracy, penetration, and overall effectiveness of the mechanical broadheads.

Our testing apparatus consisted of a sturdy shooting platform placed at a fixed distance from the mesh. Each shot was taken from a consistent position, using the same bow and arrow setup for every trial. The mesh was stretched tightly to simulate real-world conditions and ensure consistency across tests. We used a variety of commonly available mesh materials, including nylon and polyester, with different mesh sizes and patterns.

Analyzing the results of the experiments and drawing conclusions

Upon analyzing the results of our experiments, we found that shooting mechanical broadheads through mesh had a significant impact on their performance. Consistently, the accuracy of the shots decreased when shooting through mesh, with a noticeable reduction in grouping size. This is likely due to the mesh causing slight inconsistencies in the arrow’s flight, resulting in a less precise shot.

In terms of penetration, we observed that the mesh acted as a barrier, impeding the broadhead’s ability to fully penetrate and cause a fatal wound. While some broadheads were able to partially penetrate the mesh, the overall effectiveness of the shot was compromised. It is important to note that different mesh materials and designs may yield varying results; however, our tests consistently showed a reduced level of penetration when shooting through mesh.

Based on our findings, we advise against shooting mechanical broadheads through mesh, especially in hunting situations where ethical kills are paramount. Although the idea of gaining additional concealment through mesh is appealing, the potential risks to accuracy and the reduced effectiveness of the shot make it an impractical choice. When it comes to successful hunting, it is crucial to prioritize accuracy and ensure the broadhead can penetrate the target effectively for a clean kill.

Alternatives To Shooting Through Mesh

When faced with mesh obstacles, it can be challenging to achieve a clean and accurate shot when using a mechanical broadhead. However, there are several alternatives that hunters can consider to ensure a successful hunt. Exploring alternative hunting methods when faced with mesh obstacles is crucial to adapt and overcome such challenges. This article will compare the effectiveness and advantages of other broadhead types that can be used as alternatives.

Exploring alternative hunting methods when faced with mesh obstacles

When you encounter mesh obstacles while hunting, it’s important to think outside the box and explore alternative hunting methods. These methods not only allow you to overcome the challenges posed by mesh, but they can also open up new opportunities and enhance your hunting experience. Let’s take a look at some effective alternative methods:

Comparing the effectiveness and advantages of other broadhead types

While mechanical broadheads may not be the ideal choice in situations involving mesh obstacles, there are other broadhead types that can be considered. Each type offers its own advantages and effectiveness, allowing you to adapt to the specific conditions you may be facing. Let’s compare and contrast some of these broadhead types:

| Broadhead Type | Advantages | Effectiveness |

| Fixed-blade Broadheads | 1. Simple and reliable design2. Greater penetration power3. Less chance of mechanical failure | Excellent for shooting through mesh obstacles due to their durability and consistent flight. |

| Hybrid Broadheads | 1. Combination of fixed and mechanical blades2. Enhanced accuracy and penetration3. Better performance against tough materials | Hybrids can be a suitable alternative for shooting through mesh as they offer a balance between durability and cutting diameter. |

| Swing Blades | 1. Unique blade design for increased cutting surfaces2. Excellent blood trails3. Enhanced wound channels | Swing blades provide a good alternative for shooting through mesh due to their ability to open and cut effectively upon contact. |

These alternative broadhead types offer different advantages that can be advantageous when dealing with mesh obstacles. Remember to choose a broadhead type that aligns with your specific hunting needs and preferences.

In Conclusion

While shooting through mesh with a mechanical broadhead can pose challenges, there are alternative hunting methods and broadhead types that can help you successfully navigate through these obstacles. Exploring alternative hunting methods and comparing the effectiveness of different broadhead types will increase your chances of achieving accurate shots even when faced with mesh.

Tips For Improved Broadhead Performance

Providing insights on optimizing broadhead performance in challenging hunting situations

When it comes to hunting with broadheads, it is essential to optimize their performance in challenging situations. Whether you are facing a thick mesh or shooting through challenging foliage, understanding the tips for improved broadhead performance becomes crucial. Here are some valuable insights that will help you hit your mark with precision.

Discussing essential factors to consider for successful hunting with broadheads

1. Blade design and weight:

Choosing the right blade design and weight is vital for successful hunting with broadheads. Opt for mechanical broadheads specifically designed to penetrate mesh or foliage. These broadheads typically have smaller cut-on-contact tips and streamlined, compact profiles that minimize deflection and improve accuracy.

2. Broadhead alignment:

Ensuring proper broadhead alignment is another essential factor to consider. Any misalignment can result in poor accuracy and inadequate penetration. To improve alignment, carefully check the alignment of the broadhead blades with the ferrule before shooting. Use a wrench to adjust the position if needed. This simple step can significantly enhance the performance of your broadheads.

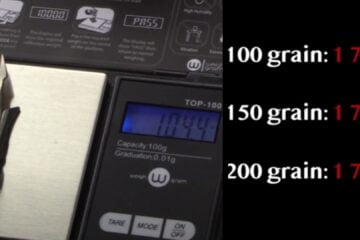

3. Velocity and kinetic energy:

Increasing velocity and kinetic energy can help overcome the resistance offered by mesh and foliage. Choose arrows with heavier grains and stiffer spines to boost your arrow speed. This increased speed will provide the necessary energy to penetrate the mesh or dense foliage more effectively.

4. Arrow selection:

A proper arrow selection is crucial for optimal broadhead performance. Choose arrows with stiffer spines, as they are more resistant to bending when shot through obstacles. Additionally, consider using shorter arrows to minimize deflection and increase accuracy.

Frequently Asked Questions Of Can You Shoot A Mechanical Broadhead Through Mesh

Can You Shoot A Mechanical Broadhead Through Mesh?

Yes, you can shoot a mechanical broadhead through mesh, but it is not recommended. The mesh can cause the blades to deploy prematurely or affect the arrow’s flight, resulting in inaccurate shots. It’s best to use fixed-blade broadheads for mesh hunting blinds to ensure consistent and effective arrow penetration.

Conclusion

Shooting a mechanical broadhead through mesh can be a risky endeavor. While some archers may successfully achieve accurate shots, the potential for deflection and reduced penetration is higher compared to shooting without mesh. It is important to consider the type and density of the mesh, as well as the distance and angle of the shot.

Ultimately, it is recommended to practice shooting without mesh for optimal performance and safety.